Our strength

High-quality products

Speed of services

High-technology systems

Long experience in the field

Our company

Modelleria 2.0 was founded in 2001 thanks to the long experience of the founder partners. Since the beginning, our core business is the design, development and manufacture of resin patterns of soles for footwear. Over the years, our company has grown and that’s what allowed Modelleria 2.0 to invest in our machines, from two to five machining centers able to increase our production capacity.

The constant attention in new technologies allowed the company to keep updated in software programs, investing in 2013 in a next-gen digital scanner capable to guarantee the production of high-quality products and to offer an excellent service of 3D digital copying.

Today the Modelleria 2.0 headquarters are organized in design office, workshop and production department and a finishing area where our experienced pattern makers work in an artisanal way the models preparing it to be delivered to the custom.

In order to find the right combination between tradition and technology, since always the company has a high-specialized staff capable to make high-quality products in line with the customer’s expectations. Today, thanks to our twenty-year professional standards and reliability, Modelleria 2.0 has become a real point of reference in the industry, offering their services to sole makers, shoes factories and printmaker at national and international areas.

Design and development

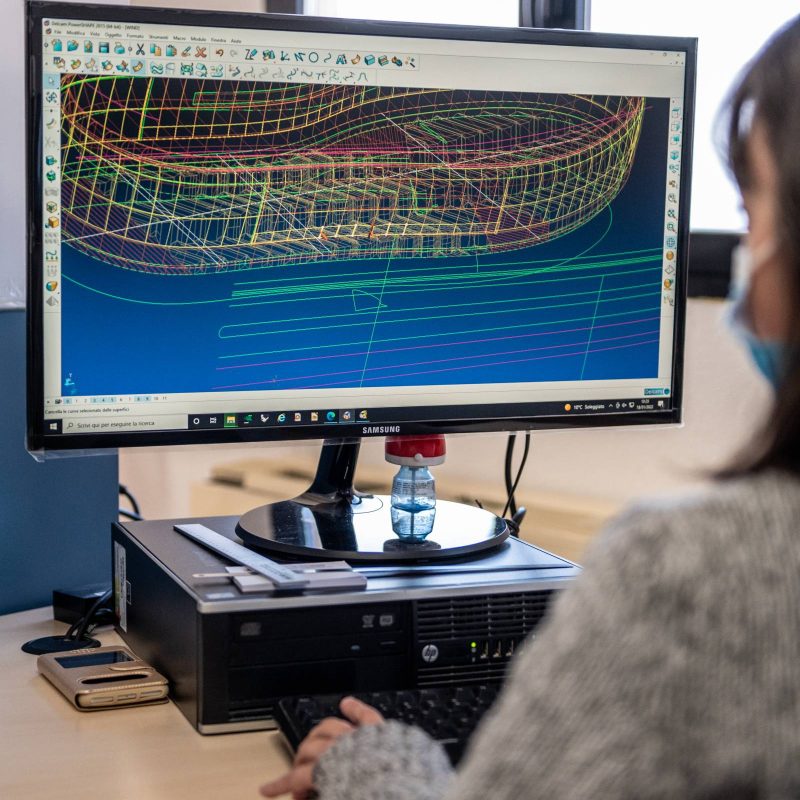

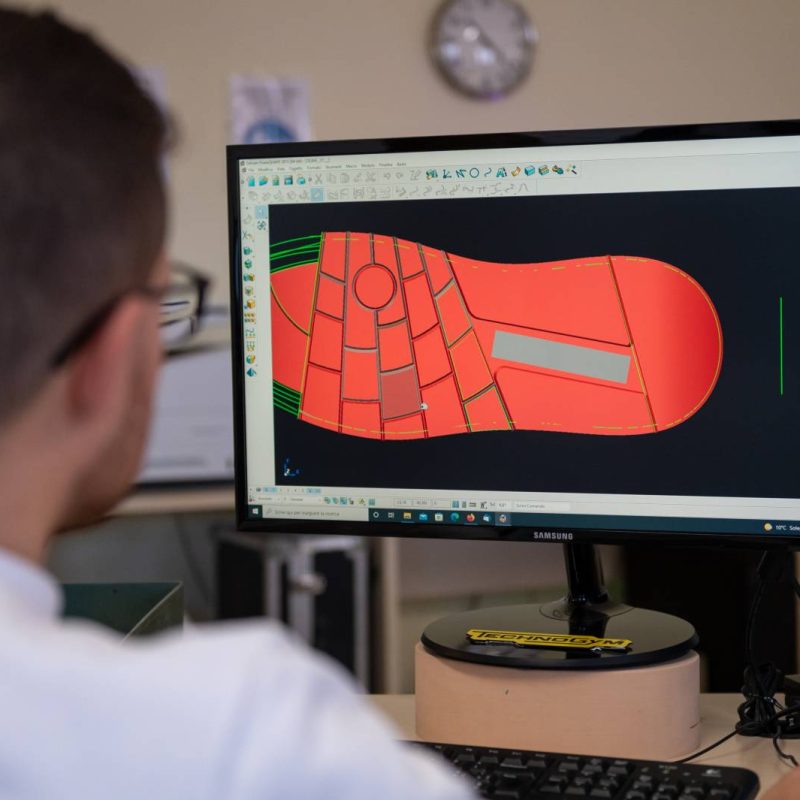

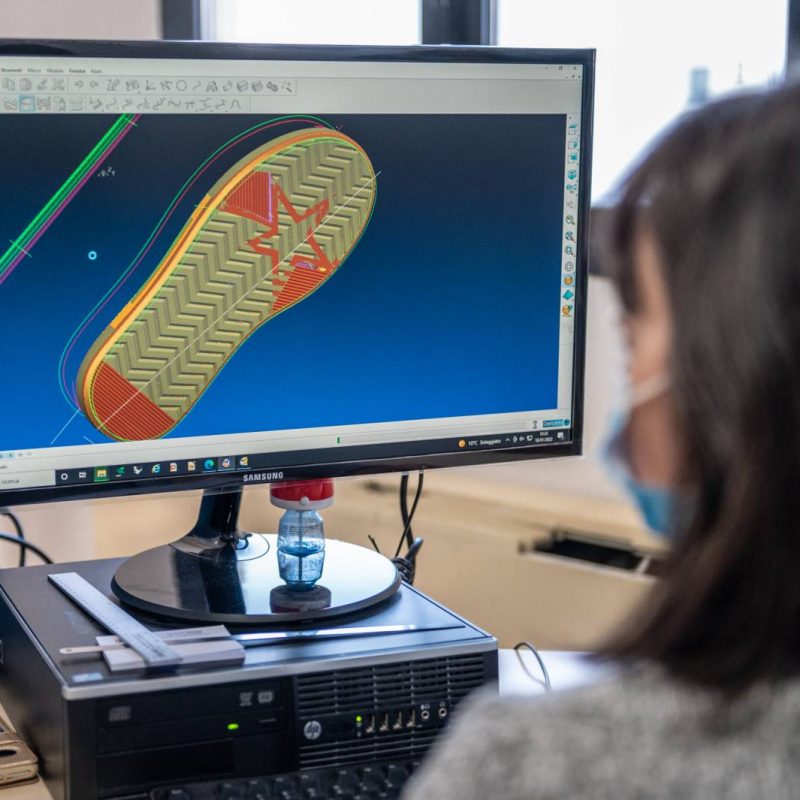

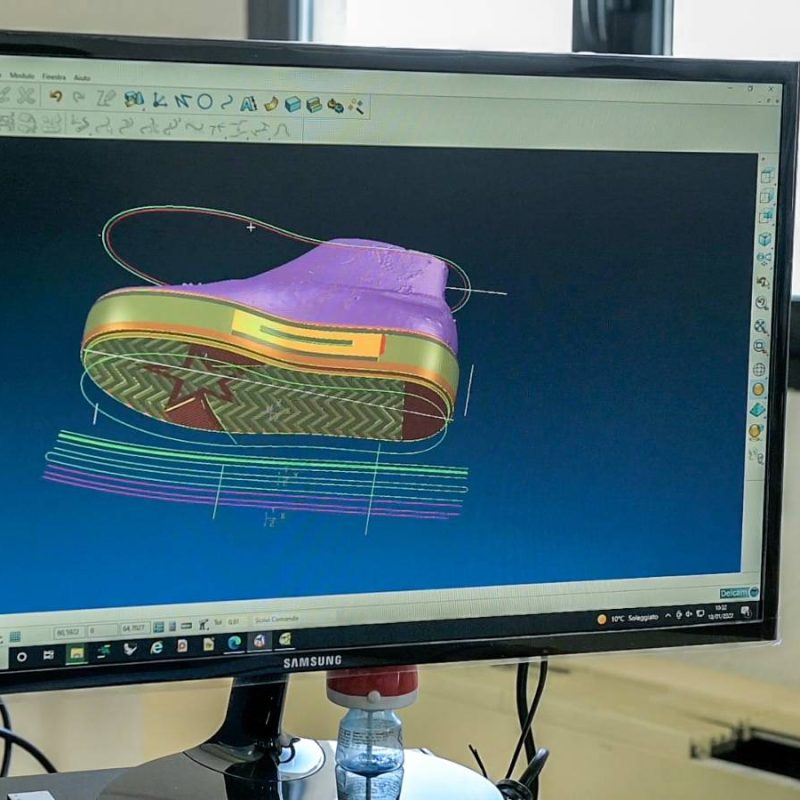

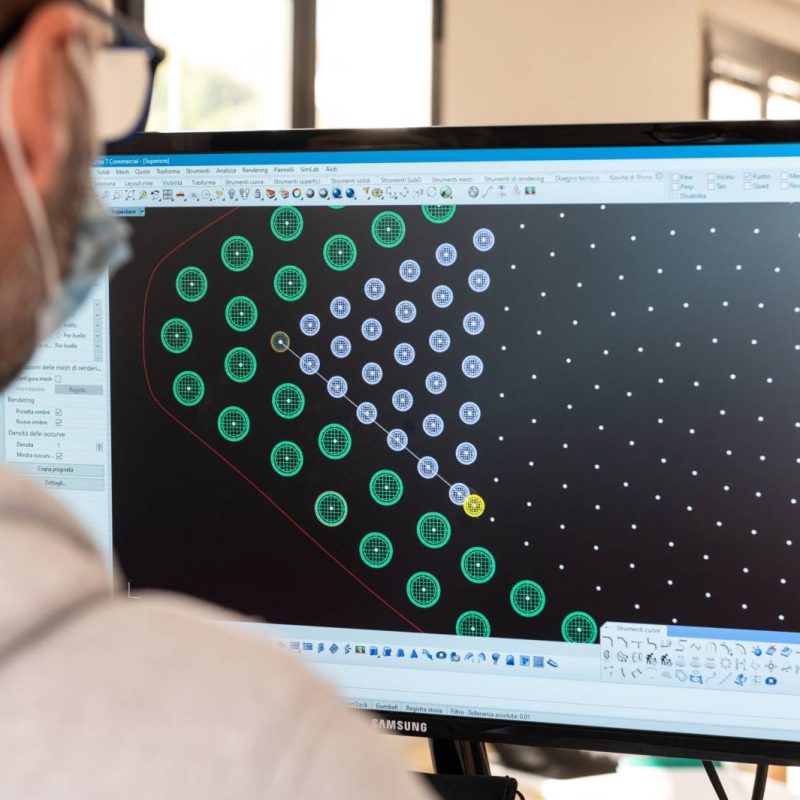

We have always attached great importance to our digital design department and that’s why Modelleria 2.0 decided to found Urano Progetta, a company specialized in high defined digital projects, designed to be developed and send to our productive department.

In order to guarantee customer’s expectations, the office make use of next-gen hardware products, technological CAD CAM programs and a high-specialized staff capable to interfacing with the customer and the operative area. When the project is ready, the sample is sent to cnc machines, programmed following the original project and activated to work the product.

Since many years, the company also invested in 3D printers capable to realize rapid prototyping of insert that can enrich the final model. If necessary for who doesn’t really know how to create the model, our expert artisans can manually realize the entire model.

Production

Since always, Modelleria 2.0 is specialized in production of resin patterns for man/woman/kid shoes soles. Once the project arrives, in order to the kind of pattern to realize, the machinery makes an estimate of production times and methods, allowing our high-specialized staff to start the production.

The operative department has five working centers, some of them equipped with chargers that can guarantee the automatic night production of the patterns, ensuring the correction of any faults through the remote video control of the machinery.

Finishing

We give great relevance to the finishing department, the last phase before the product delivery. Our experts in fact, following the work-processing tab, can artisanal refine every piece through accurate polishing with limes, abrasive papers, specials glues and the manual application of rubber plates.

In accord to the complexity, the inlays and the drawings of the patterns, the expert artisan can manually create the product, all with the aim to realize a piece in accordance with the initial project and with the customer’s expectations.

Contacts

Address

Viale 8 Marzo, 5

63813 MONTE URANO (FM)